What You Should Know About CNC Machining PEEK

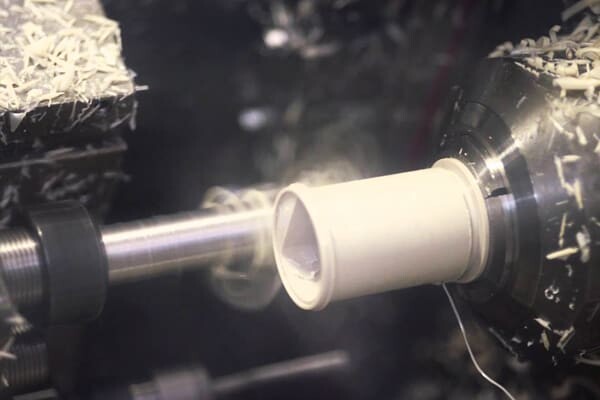

CNC machining shops typically stock bars with diameters ranging from 6mm to 150mm. Before machining, PEEK must be stress relieved by an annealing process. This is to prevent the formation of surface cracks and internal stress due to heat generated during cutting. In long-time PEEK machining, additional annealing procedures are required, such as an annealing procedure before roughing, and a second annealing before finishing to eliminate the possibility of crack formation. The cost factor for PEEK CNC machining is 0.9 compared to steel 12L14.