Rapid Prototyping & Rapid Manufacturing Expert

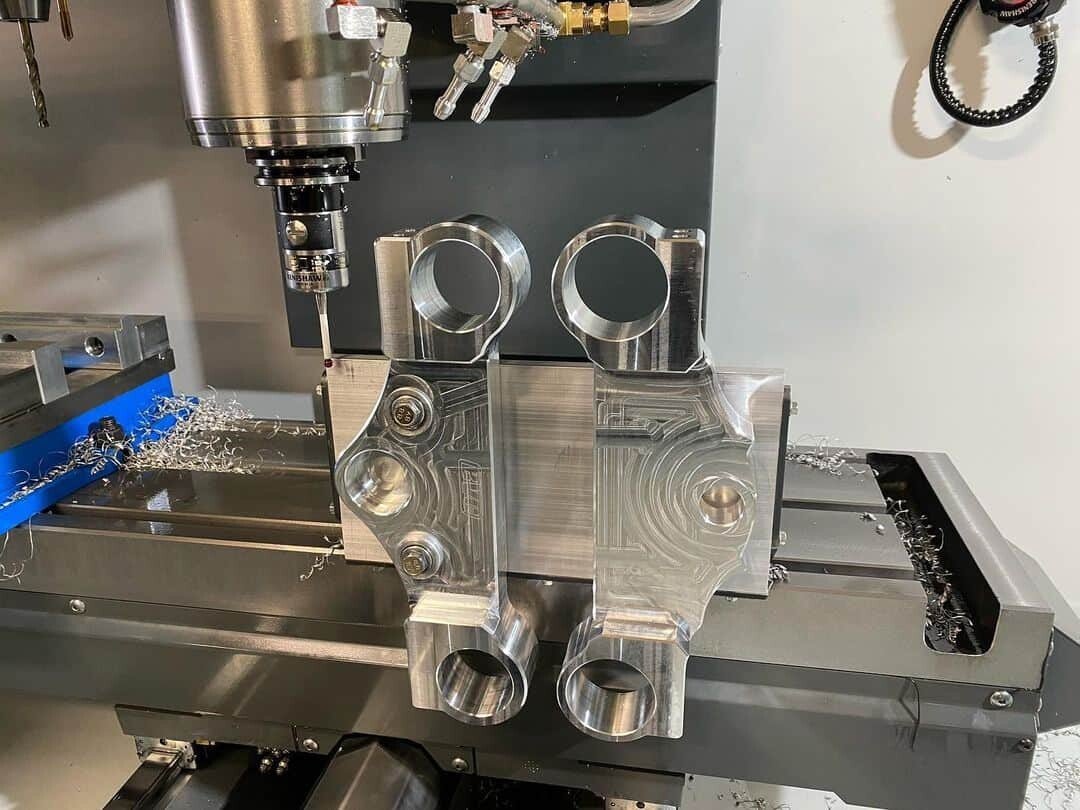

Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion

Method for Selecting Positioning Datum for CNC Machining Parts

During CNC machining process, the selection of the Positioning datum determines the quality of the parts, and it plays a decisive role in ensuring the dimensional accuracy and mutual position accuracy of the parts. At the same time, it also has a great influence on the processing sequence between the surfaces of the parts. When using a fixture to install the workpiece, the choice of positioning datum will also affect the complexity of the fixture structure, because this requires the fixture to withstand large cutting forces and meet the positioning accuracy requirements. Therefore, the choice of positioning datum is a very important factor affecting the CNC machining process. So how do we choose the positioning datum when machining parts with a CNC machining center? Here is a brief introduction:

1.Ensure the Accuracy of The Positioning

The selected datum should be able to ensure the accuracy of the positioning of the workpiece, and it is convenient to load and unload the workpiece, and the positioning and clamping of the workpiece can be completed quickly, the clamping is reliable, and the fixture structure is simple enough to make.

2.Minimize the Calculation of The Dimensional Chain

The selected datum of the CNC machining center and the dimensions of each processing part are simple to calculate, minimize the calculation of the dimensional chain, and avoid or reduce the calculation links and calculation errors.

3.To ensure the accuracy of various processing, following principles should be followed When determining the positioning datum of specific parts:

1) The origin of the workpiece coordinate system, also named the “programming zero point”, do not necessarily have to coincide with the positioning datum of part made, but there must be a definite geometric relationship between the two. The main consideration for the selection of the origin of the workpiece coordinate system is to facilitate programming and measurement. For parts with high dimensional accuracy requirements, when determining the positioning datum, it should be considered whether the coordinate origin of the CNC machining center can be accurately measured by the positioning datum.

2) When both the processing datum and the processing of each station are completed on the CNC machining center, the selection of the positioning datum needs to consider the completion of as much processing content as possible. For this reason, it is necessary to consider a positioning method that facilitates all surfaces to be processed. For example, for a box, it is best to use a fixed two-sided positioning method to facilitate the processing of other surfaces by the tool.

3) Try to choose the design datum on the part as the positioning datum. This requires that when rough CNC machining, consider what rough machining datum to use to machine each surface of the precision-machined datum, that is, each positioning datum used on the CNC machining center should be processed in the previous ordinary machine tool or other machine tools, so it is easy to ensure the accuracy of the correlation between the processed surfaces of each station.

4) When the positioning datum of the part machined from CNC machining center is difficult to overlap with the design datum, the assembly drawing should be carefully analyzed to determine the design function of the part design datum, and the geometric tolerance range between the positioning datum and the design datum should be strictly specified through the calculation of the dimensional chain to ensure machining accuracy.

5) When the station processing including the design datum cannot be completed on the CNC machining center at the same time, the positioning datum and the design datum should be overlapped as much as possible. At the same time, it should be considered that after positioning with this datum, all the critical precision parts can be processed with one clamping.