Rapid Prototyping & Rapid Manufacturing Expert

Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion

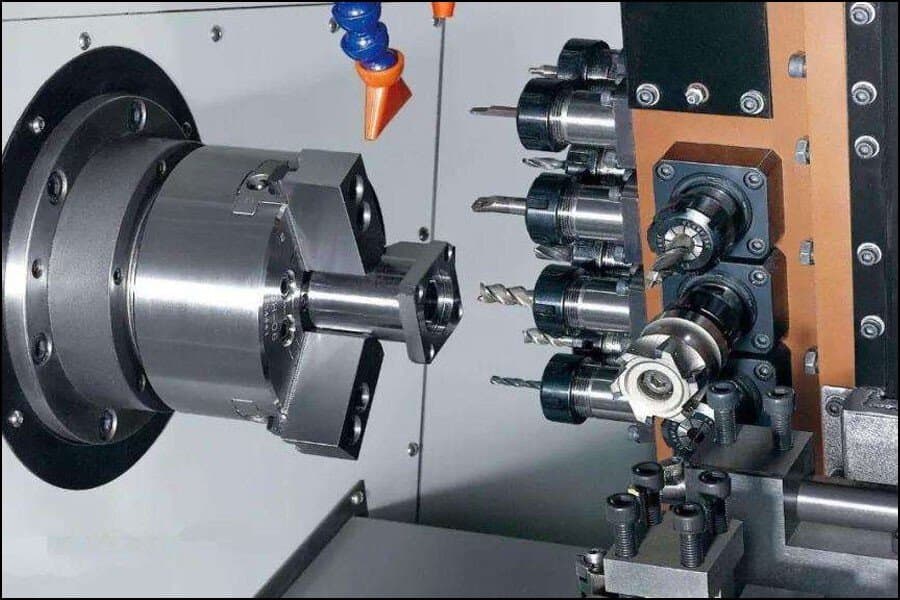

To talk about Turning and Milling Combined Machining

With the continuous development of numerical control technology, computer technology, machine tool technology and processing technology, traditional processing concepts can no longer meet people’s requirements for processing speed, efficiency and precision. In this context, composite processing technology came into being. Generally speaking, composite processing refers to the general term for processing technologies that can complete different processes or different process methods on one processing equipment.

The current compound machining technology is mainly manifested in two different types, one is the compound of different processing methods based on energy or movement mode; the other is based on the principle of process concentration and mainly focuses on mechanical processing technology. Compound, turn-milling compound machining is one of the fastest-growing processing methods in this field in recent years.

The current aviation product parts are characterized by multiple varieties and small batches, complicated process, and the overall thin-walled structure and difficult-to-machine materials are widely used. Therefore, long manufacturing cycles, large material removal, low processing efficiency, and processing deformation are common in the manufacturing process. Seriously waiting for the bottleneck.

In order to improve the processing efficiency and processing accuracy of aviation complex products, craftsmen have been seeking more efficient and precise processing methods. The emergence of turning-milling compound processing equipment provides an effective solution for improving the machining accuracy and efficiency of aviation parts.

Compared with conventional numerical control processing technology, the outstanding advantages of compound processing are mainly manifested in the following aspects.

(a) Shorten the product manufacturing process chain and improve production efficiency.

Turn-milling combined processing can complete all or most of the processing procedures in one clamping, thus greatly shortening the product manufacturing process chain. In this way, on the one hand, the production auxiliary time caused by the change of clamping is reduced, and at the same time, the manufacturing cycle and waiting time of the fixture are reduced, and the production efficiency can be significantly improved.

(b) Reduce the number of clamping and improve the machining accuracy.

The reduction in the number of card installations avoids the accumulation of errors caused by the conversion of positioning datums. At the same time, most of the current turning-milling compound processing equipment has the function of online detection, which can realize the on-site detection and precision control of key data in the manufacturing process, thereby improving the processing accuracy of products.

(c) Reduce floor space and reduce production costs.

Although the unit price of turning-milling compound processing equipment is relatively high, due to the shortening of the manufacturing process chain and the reduction of equipment required for the product, as well as the reduction of the number of fixtures, workshop floor space and equipment maintenance costs, the overall fixed assets can be effectively reduced The cost of investment, production operation and management.

The key technology of compound machining

Although composite processing has advantages that cannot be compared with conventional single processing, in fact, the utilization rate of turning-milling composite processing in the field of aviation manufacturing has not been fully utilized. The key reason is that the application time of turning-milling composite machining in the field of aviation manufacturing is still relatively short, and the turning-milling composite machining technology, numerical control programming technology, post-processing and simulation technology suitable for the structural characteristics of aviation parts are still in the exploration stage.

In order to give full play to the performance of turning-milling composite processing equipment and improve the processing efficiency and precision of products, it is necessary to comprehensively overcome and solve the above key foundations and realize integrated applications.

1. Technology of CNC turning and milling combined machining

Different from conventional machining equipment, a turn-milling compound machining center is actually equivalent to a production line. How to formulate a reasonable process route, clamping method and select a reasonable tool according to the process characteristics of the part and the process characteristics of the turn-milling compound machining is the key to realize efficient precision machining.

Process concentration is the most distinctive technological feature of composite machining. Therefore, a scientific and reasonable process route is the key factor to improve the efficiency and precision of turning and milling compound machining.

Take the S192F CNC milling and turning compound machining center of Swiss Baomei Company as an example. This machine tool has functions such as five-axis milling, turning, boring, drilling, sawing and automatic feeding.

Strong forward-looking, high-speed interpolation and other functions, especially suitable for high-speed precision machining of shafts, rotary parts and other parts. In the machining of aviation impellers, this machining center has outstanding advantages.

When the bar is used as the impeller blank, the conventional impeller machining route first uses the CNC lathe to turn the outer contour of the impeller, and then finishes the benchmark; on this basis, uses the five-axis CNC machining center for slotting, roughing, and semi-finishing As well as the finishing of the profile and hub; finally the hole machining is done on a 5-axis machining center or drilling equipment.

However, the S192F milling and turning machining center can not only complete all the machining of the above-mentioned processes through one-time clamping, but also realize the batch machining of impellers through the functions of sawing and automatic feeding when using bar materials. The whole process can be processed without manual intervention.

All done automatically. The setting of the process route can be done in the following way: the main shaft clamps the bar material→rough turning the outer contour of the impeller→finishing the outer contour→five-axis milling and slotting→rough machining of the runner→semi-finishing of the runner→finishing of the runner→drilling Hole→Clamping of the back spindle→Turning the bottom plane of the impeller→Drilling.

It can be seen that the entire impeller machining process can be completed in one clamping, and the machining efficiency and precision can be greatly improved.

For the cnc turning-milling machining center with double turrets, the equipment with double turrets has a dual-channel control system, the upper and lower turrets can be controlled separately, and the synchronous machining can be realized through the synchronization statement in the code.

In order to give full play to the machining capability of the equipment, the simultaneous operation of multiple processes of parts can be realized through the synchronous operation of the double tool holders under the premise that the machining conditions permit.

Through the synchronous setting of the upper and lower tool holders, the rough boring of the inner hole can be completed while roughing the shape, thereby further improving the machining efficiency. Through the synchronous movement of the upper and lower tool holders, a series of hole machining is completed, which not only improves the machining efficiency, but also reduces the influence of workpiece deformation by offsetting the axial force of the drilling hole. In order to realize this function, it is necessary to conduct systematic and in-depth research on the process plan in the early stage of process design, determine the serial and parallel sequence of the process route, and realize the above functions through a reasonable combination of machining programs.

2. CNC programming technology for turning and milling compound machining

The development of turn-milling compound machining technology also puts forward higher requirements for NC programming technology, which is also a bottleneck link that restricts turn-milling compound machining equipment in actual production and application.

Due to the short application time of turn-milling composite machining in actual production, in the absence of professional composite machining solutions, it is usually to use general-purpose CAM software to plan part of the machining program, and then the craftsman manually integrates the program to meet Composite machining machine tool requirements for machining programs.

This solution places very high demands on craftsmen. Compared with the traditional NC programming technology, the programming difficulties of turning and milling compound machining are mainly reflected in the following aspects.

(a) There are many kinds of crafts. For craftsmen, not only must they be able to master the programming methods of various machining methods such as CNC turning, multi-axis milling, and drilling, but also need to accurately define the connection between processes and the way of advancing and retreating tools. Therefore, when performing NC programming, it is necessary to have an intuitive understanding of the process model and the distribution of the machining allowance after the current process is completed, so as to facilitate the programming of the next process and the setting of the advance and retreat tools.

(b) The sequence of serial and parallel in the programming process must be determined in strict accordance with the process route. Many parts can be processed from raw materials to finished products when they are processed on the turn-milling compound machining center, so the results of the machining program must be consistent with the process route. At the same time, multi-channel parallel machining also needs to be considered comprehensively in the process of NC machining programming. It can be seen that in order to achieve efficient compound machining, an integrated process solution of process-programming-simulation should be developed.

(c) The current general CAM software does not support some functions of turn-milling compound machining. Compared with conventional single equipment machining, the machine tool movement and machining functions of turning and milling compound machining are much more complicated. The current general-purpose CAM software is not enough to fully support the programming of these advanced functions, such as online measurement, sawing, automatic Feeding, tailstock control, etc. Therefore, the programs compiled by general CAM software still need a lot of manual or interactive methods before they can be applied to automatic turning and milling compound machining.

(d) Integration of machining procedures. At present, the NC programs compiled by the general CAM software are independent of each other. To realize the complex automatic complete machining such as turning and milling, it is necessary to integrate and integrate these independent machining programs. This integration must be guided by the process route of the parts, first determine which programs are parallel, and then determine the machining sequence of different process methods, and give accurate tool change, clamp replacement, datum conversion, and tool advance and retreat instructions wait.

It can be seen that it is very difficult to compile NC programs for turning-milling combined machining, and the current general-purpose CAM software still has many defects and deficiencies in turning-milling combined machining. In order to make up for these shortcomings, it is a more realistic solution to develop a special programming system suitable for product technology and compound machining equipment on the basis of the existing general-purpose CAD/CAM software. On the one hand, it reduces the repeated investment in software purchase, and at the same time, it can avoid defects such as unreusable process knowledge and complicated staffing caused by non-uniform programming platforms.

3. Post-machining technology of turn-milling compound machining

Corresponding to the NC programming technology, due to the complex process method and many moving parts, the turn-milling combined machining puts forward higher requirements for the current post-machining software and technology. Compared with conventional CNC equipment, the difficulties of its post-machining are mainly reflected in the following aspects.

(a)The connecting movement between different processes requires strict accuracy. Due to the wide variety of machining techniques performed on the turning-milling compound equipment, the automatic switching of machining methods, tools, and moving parts must be completed in a timely and accurate manner after the current process is completed to ensure the correctness and safety of the machining process.

In order to achieve this goal, on the one hand, it is required to set a reasonable way of advancing and retreating the tool and the timing of automatic tool change, coolant on and off, and more importantly, it is necessary to set the position of other non-moving parts when machining the current process . Only in this way can the collision between the moving parts and non-moving parts of the machine tool during tool change and machining be avoided, and the machining process can be ensured to be safe and stable.

(b)It is necessary to automatically judge the process sequence and NC program. Due to the relatively long process route in compound machining, it is not only inefficient but also prone to errors to rely on manual organization and integration of post-completed NC codes. The ideal solution is to be able to automatically determine the machining sequence and the process method contained in the tool position file during the post-machining, and to automatically maintain it in the NC code after the post-machining is completed.

For this reason, the tool position file information after the NC programming is completed not only needs to contain the corresponding process method and tool position information, but also needs to include the corresponding machining sequence, the type and number of the tool used, so that it can be processed in the post-machining process. Achieve automatic determination of process sequence, process method and tool.

(c) Post-machining technology of different machining methods. The post-machining program of turn-milling combined machining not only requires the post-machining of multi-axis CNC milling, turning, and drilling, but also the functions of sawing, automatic feeding, tailstock control, and program cycle call. The post-machining algorithm of milling compound machining basically includes the post-machining methods of all types of existing CNC machining processes, and it must also be able to achieve seamless integration and motion connection between different machining methods.

(c)Make full use of the advanced functions of the control system. At present, the CNC systems used for turning and milling compound machining centers are all very advanced control systems, such as the FANUC 31i system used by Baomei S192FT and the SINUMERIK840D system used by WFL 150.

Most of these advanced control systems have advanced functions such as automatic feed optimization, tool vector smoothing, super forward-looking and high-speed, high-precision interpolation. Therefore, it is necessary to reflect the functions of these advanced CNC systems in the appropriate position in the machining code completed in the post-machining stage, so as to realize the full utilization of the performance of the turning-milling compound machining equipment.

(d)machining and calling of non-cutting functions. In addition to the cutting functions such as turning, milling, drilling, and boring, the compound machining machine tool also has non-cutting functions required for the transition between various processes, such as automatic feeding, unloading, spindle docking, tailstock control, etc.

In the post-machining, these functions need to be called as a common module for the program, and the order and timing of calling need to be determined according to the process route. These functions are not available in current post-machining software.

4. Simulation technology of turning and milling compound machining

Due to the many moving parts and complex functions of turn-milling compound machining, the machining simulation after the programming is completed is particularly important.Due to the fact that the turn-milling composite machining of my country’s aviation manufacturing plants has been put into actual production for a short time, there is no mature simulation application technology at present.Therefore, most manufacturers verify and optimize the program through trial cutting machining, which leads to long process preparation cycles and development. High risk and machining costs.

In order to improve the application level and programming efficiency of turn-milling compound machining, it is necessary to vigorously promote the application of simulation technology.At present, the software used for the simulation of turning and milling combined machining mainly includes TopSolid, Gibbs, etc., but these software are generally expensive, and the introduction of my country’s aviation manufacturing field is seldom.In fact, the simulation of turning-milling combined machining can also be realized with the help of current general-purpose CNC machining simulation software (such as Vericut, NCSimul, etc.), according to the structure, motion characteristics, special functions and CNC system of turning-milling combined machining equipment, through customization and macro Function development realizes the motion simulation of the machining process.

The use of general CNC machining simulation software to realize the simulation of turn-milling combined machining requires the establishment of a relatively real machine tool environment in the simulation system first, and the focus is on the establishment of the relative motion relationship and geometric position relationship between the moving parts of the machine tool.

On this basis, establish the tool library and corresponding tool numbers used in the machining process. Then configure the numerical control system of the machine tool equipment and the machining benchmark of the numerical control program, and load the post-completed NC code into the simulation system, and then the simulation work of the machining process can be performed. Different from conventional NC machining, some functions (such as multi-channel machining, tailstock control, etc.) need to be completed through the development and customization of macro functions.

Application prospects and development suggestions of turning and milling composite machining technology

In recent years, turning and milling compound machining centers have been introduced in my country’s aircraft, aero-engine and accessory factories and other aviation manufacturers. The types of equipment mainly focus on the turn-milling compound series products of Austrian WFL company and the milling-turning compound machining center of Swiss Baomei company.

However, due to the short time in practical application, there is generally a lack of mature machining technology, programming methods and post-machining technical means that are compatible with product process characteristics and equipment process characteristics. Therefore, the currently introduced turn-milling compound machining equipment is basically at a relatively low operating level.

The main problems faced in the manufacturing process of aviation products are highlighted in the long process route, complex process, low machining efficiency, serious machining deformation, and high machining cost. Turn-milling composite machining has a very broad application in both aircraft manufacturing and engine manufacturing. development space.

For example, the milling process of the overall frame of the aircraft fuselage usually needs to go through blanking/blank preparation, datum machining, rough machining inner shape, rough machining shape, finishing datum, semi-finishing and finishing inner shape, semi-finishing

Dozens of processes, such as finishing and finishing shape, hole machining, fitter dressing, testing, etc., can be completed with multiple flipping and clamping.

At present, the overall blisk machining in the field of aero-engines also uses integral forging blanks, which can only be completed after dozens of processes such as turning and milling, milling, polishing, surface treatment and strengthening, and flaw detection.

These parts often have a long manufacturing cycle, and the machine time usually reaches hundreds of hours, and many different types of CNC machine tools and a large number of fixtures, tools, measuring tools, etc. are required in the machining process. In addition, the repeated replacement of clamping not only causes the waiting time in the part manufacturing process to be too long, which affects the production cycle, but also causes the accumulation of clamping errors, thereby affecting the dimensional accuracy and machining results of the parts.

The combined turning and milling machining can realize all or most of the processes of the above-mentioned typical aviation parts through one clamping, thus providing a new way for the efficient and precise machining of complex aviation parts.

Its application advantages are mainly reflected in the following aspects:

(a)The number of clamping times is significantly reduced, improving machining efficiency and eliminating errors caused by changes in machine tools and clamping methods.

(b)The process is more concentrated, which can significantly shorten the machining process chain, reduce waiting time and machine non-working time.

(c)On the premise of not changing the positioning state, realize the machining process of various machining methods such as turning, milling, drilling, etc., reduce the number of fixtures, and ensure the consistency of dimensional accuracy.

(d)Most of the current turning-milling composite machining has the function of online measurement, which can be used to measure the machining results in the process and between processes in situ, so as to realize the precision control of the entire machining process. It can be seen that these advantages of turning-milling composite machining equipment can effectively make up for the shortcomings in the current manufacturing process of aviation complex parts, and can significantly improve the machining accuracy and efficiency of products.

In order to give full play to the machining efficiency of advanced composite machining equipment and further improve the manufacturing efficiency and quality of aviation products, it is urgent to carry out the following aspects of work.

(a) In combination with the technological characteristics of aviation product parts, conduct in-depth research on the composite machining technology that is compatible with it, including the formulation of process routes, the reasonable selection of clamping methods, tools, cooling and cutting parameters, etc.

(b) According to the motion structure of compound machining equipment and the process characteristics of products, develop and customize corresponding CNC programming, post-machining, cutting simulation and other systems to form an integrated solution of process-programming-post-simulation and reduce compounding machining requirements for craftsmen.

(c) Form process specifications. Combining the process experience accumulated in simulation, trial cutting and actual production, a solidified process specification suitable for turn-milling composite machining is formed to guide the subsequent machining of other parts.

(d) Pay attention to the cultivation of talents. Composite machining equipment is the representative of cutting-edge technology in the field of mechanical machining at present. Both process preparation and operation and maintenance are more complicated than conventional equipment. A high-level R&D team is the key to achieve healthy and efficient operation of equipment.

Conclusion

The current compound machining equipment is developing in the direction of larger process range, higher efficiency, large-scale and modularization. The field of aviation product manufacturing has always been an important stage for advanced manufacturing technology to play a role.

With the acceleration of the upgrading of aviation products, machining equipment with scattered processes will gradually be replaced by flexible automation equipment with centralized processes. Broader development and application space.