Rapid Prototyping & Rapid Manufacturing Expert

Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion

The Application Field of 5-Axis CNC Machining Center And Machiningtips

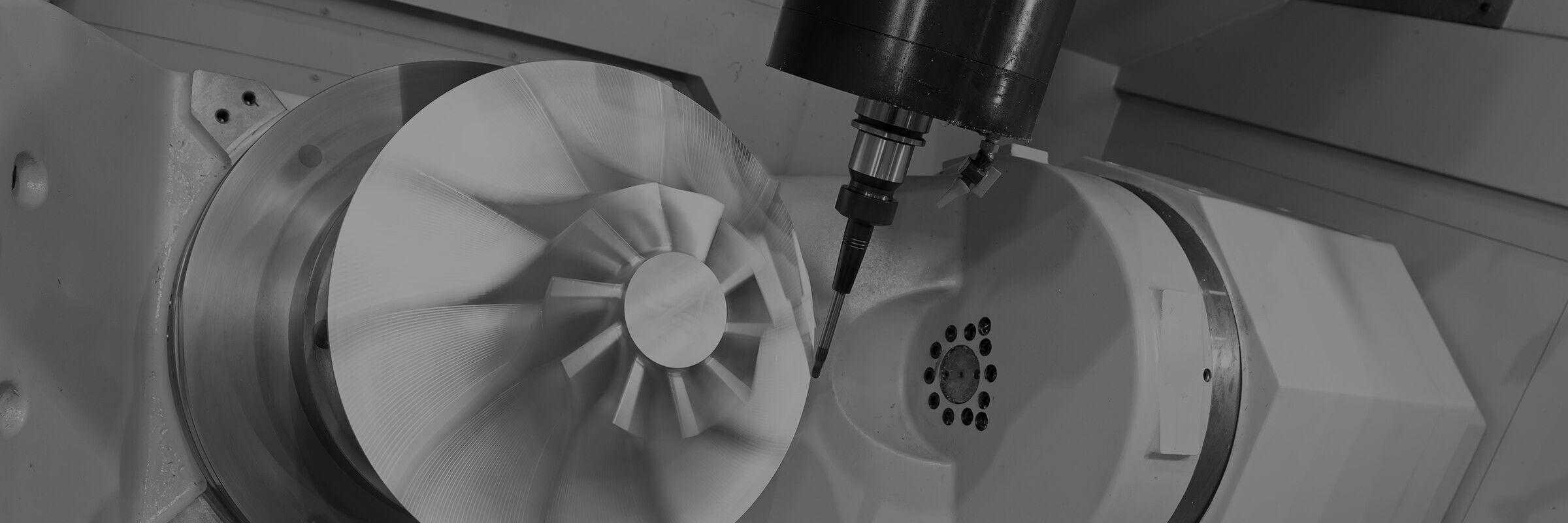

5-Axis CNC machining center with high-tech and high precision and usually applied to mass production of the parts with sculptured surface, complex geometries, multi process and high precision. 5-Axis CNC machining plays a significant role in aerospace, military, scientific research, precision instrument and machinery, high precision medical equipment and so on for every country. Currently, 5-Axis CNC machining is the only means to machining impeller, blade, blade propeller, heavy-duty generator rotor, steam turbine rotor, large diesel engine crankshaft and so on.

5-axis CNC machining services

At DDPROTOTYPE, we specialize in rapid prototyping manufacturing & mass production over 20+ years, till of today we have 40+ senior engineers with range of technologies can provide professional solutions. 50+ kinds of surface finishing options, over 60+ certified materials in metal/plastic can cover different rapid prototyping needs. DDPROTOTYPE maintaining long term relations with world-class companies in various industries, such as medical device, Electronic consumer products, Automotive, Robotic, Aerospace etc. 7*24 hours one-on-one quickly respond, As fast as 3 days for delivery. Keep learn or contact us for getting instant quote.

DDPROTOTYPE is very familiar with 5-axis CNC machining services and has 4sets 5-axis CNC machining centers from JINGDIAO. Based on our many years experience,Following, let we talk about the mainly tips & application field of 5-Axis CNC machining.

5-Axis machining center of box-type parts

Box parts refer to the parts with more than one hole and multi-cavity. Such parts happened in sector as machinery, automotive, aircraft manufacturing and so on. For example, like engine crankcase, gearbox casing, headstock of lathe, spindle box, diesel engine block, and gear pump body and so on.

One time clamped on the auxiliary fixture, box-type parts are machined on the 5-Axis machining center can be completed around 60%-95% procedure contents, compare to 3-Axis & 4-Axis CNC machining center. The precision consistency of the part is good, quality is stable, the production cycle can be shortened and the cost can be reduced. For the part more machining stations and request worktable rotate the angle for several times, generally choose horizontal machining center to machining. When the machining stations not too much and the span is not large of the part, we can choose vertical machining center and start machining from one end.

5-Axis machining center of sculptured surface parts

Sculptured surface parts occupied a large proportion in aerospace, automotive, shipbuilding, military defense and so on, such as impeller, blade propeller, and variety of curve-surface cavity die, etc. When there is no machining interference area or blind area and as far as the machining possibility is concerned, the complex surface can be machined by using the ball end milling cutter and 3-Axis machining center, and the precision is high but the efficiency is low. If the work piece with machining interference area or blind area, it must take 4-Axis machining center, 5-Axis machining center into consideration for processing.

5-Axis machining center of irregular parts

Special–shaped parts are refer to irregular shape parts, most will request multi-stations mixes machining of point, line, surface, such as bracket, base, contour plate and so on. The rigidity of irregular shape parts is poor generally, and the deformation is out of control from clamping and cutting, the precision can’t be guaranteed also. At this time, we can use 5-Axis machining center to machining, adopt reasonable process, one time or twice clamping can complete multiple processes or all procedure contents.

5-Axis machining center milling plate parts and sleeve parts

Sleeve parts or shaft parts with key groove, radial hole, and end face distributed holes system and curved surface, as well as plate parts with much holes structure process, suitable for use 5-Axis machining center to do machining. Curved surface part distributed hole system on end face generally using vertical machining center, and using horizontal machining center to machining the parts with radial hole.

Features of 5-Axis machining center compared with ordinary machining centers

1.Suitable for the machiningof complex special-shaped parts

5-Axis CNC machining center can applied to machining the complex parts which hardly or basically cannot process by normal machining center, so it is widely used in aerospace, shipbuilding, mold and other machining industries.

2.High machiningprecision

5-Axis CNC machining center can do completed inspection for the size analysis of the material through five-axis positioning machining.

3.Stable and reliable machining

Realize computer control, eliminate human error, good machining consistency of the part, and stable quality.

4.High flexibility

When the machining object is changed, it is generally only necessary to change the numerical control sequence, which shows good adaptability and can save production preparation time. Basically, the 5-axis CNC machining center can form an automated production system with higher flexibility.

5.High productivity

The 5-axis CNC machining center has high machining accuracy, high rigidity and will automatically select the favorable machining amount. The productivity of the 5-axis machining center is high, which is around 3 to 5 times compare to ordinary machining center. It can cope with some complex parts’ machining, and production efficiency can be improved more than ten times or even dozens of times.

6.Good production conditions

The machine tool has a high level of automation, the operator’s work intensity is greatly reduced, and the working environment is better.

7.Conducive to management

The adoption of 5-axis machining center is conducive for computer control and production management, and creates conditions for the realization of the automation of the production process.

The 5-axis CNC machining center draw the attention from the world with its outstanding flexible automation performance, excellent and stable accuracy, agile and diversified functions, and has become a central technology in advanced production technology. On the other hand, through continuous research, the in-depth application of information technology has hurriedly advanced the further promotion of the 5-axis machining center. The 5-axis machining center is important basic equipment in the machine tool manufacturing industry, so its development has always attract people’s attention.